Nylon zippers come in a variety of lengths, and are ideal for use in upholstery, outdoor cushions, pillows, and workroom projects. Many of these zippers are available in rolls. These are a convenient way to find the exact lengths needed for your projects. In addition to rolls, you can also buy individual zippers.

Coil zippers

Coil zippers are a type of zipper made with coiled monofilament teeth. These teeth are then sewn onto the side tape with polyester thread. The plastic teeth of coil zippers are more durable than the molded teeth of standard zippers. These zippers are usually used in lightweight, medium, and heavy-weight fabrics.

Coil zippers have many advantages over traditional toothed zippers. Nylon coil zippers are strong and durable, and they are flexible. They prevent luggage from bursting, and they can be repaired simply by zipping or unzipping them. They are also bi-directional, meaning they can be attached to a garment in either direction. They are most commonly used in apparel, but are also used in sporting goods, luggage, and automobiles.

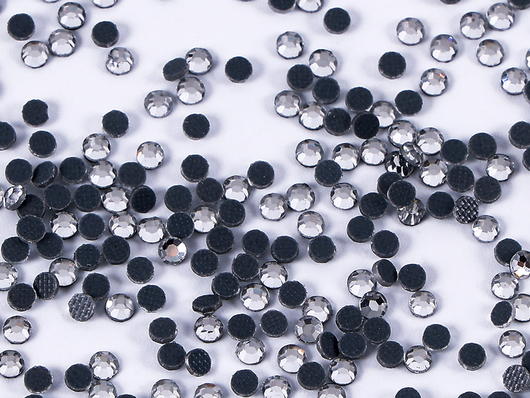

Coil zippers come in many different styles. They can be invisible, visible, and even chunky. They are available in a wide range of colors and lengths. Some are available with rhinestone teeth, while others are plain, with a molded tooth.

Extruded zippers

Extruded nylon zippers have been manufactured for several decades. Several advantages of this material make it ideal for zippers. The material has good tenacity and even yarn size. It can be easily operated and has low consumption. Extruded nylon zippers can be produced with high precision. Furthermore, they can be produced in different lengths as per the requirements of the buyer.

This type of zipper is also called a nylon coil zipper. It is made from continuous coils of nylon monofilament and is sewn onto polyester tape. It is flexible and comes in a wide range of colors. It is ideal for outdoor gear and is widely used in the luggage industry. It comes with sliders on both sides of the zipper chain.

Extruded nylon zippers are a popular choice for zippers in clothing. They come in various sizes and can be made of a variety of materials, including plastic and metal. This material is lightweight and durable. They are able to zip through fabric without any difficulty and are ideal for garments that don't have many curves. Metal zippers can be made of two different constructions: some are constructed with a single long wire while others have the teeth die-cast onto the tape. Different finishing treatments are used for a unique look and feel.

Invisible identical zippers

Invisible Identical Zippers are an option for those seeking a clean finish on their sports or outdoor apparel. These zippers are not a true invisible zipper since they can not be sewn to the teeth, but they provide a sleek, clean look. The teeth are on the wrong side of the garment so the zipper is barely visible when opened or closed.

The teeth of an invisible zipper are hidden behind the tape that makes it virtually invisible when closed. This type of zipper is often used on skirts or dresses, but can also be used in home furnishings. They are available in many different sizes, tape colors, and weights. Some products are made with continuous zipper chains which allow for custom sizing.

These zippers are available in sizes of four, six, and 10 mm. They contain a chain made of polyester monofilament. The chain is thermoset before sewing, and the zipper is then stitched to the tape. These invisible zippers are used in clothing because of their lightness and ease of use.

Plastic molded zippers

The manufacturing process of plastic molded nylon zippers consists of many steps. First, a zipper is inspected for its durability and strength. The zipper is tested for tensile strength using a tensile testing machine. This machine attaches a gauge to the zipper tooth, which measures how much force is needed to separate it from the cloth. A zipper that meets the required strength value is considered to be of high quality.

The teeth of plastic zippers are formed by a molding process. The molds are flat and are connected by two cords. The semi-molten plastic is then fed into the mold, where it solidifies. A machine then bends the teeth into a U-shape, where they can then be sewn onto the cloth tape.

Another step in the manufacturing process involves assembling the zipper parts. One chain connects the zipper parts, and the other chain connects the teeth. Reinforcing tape is placed at the midpoint. Two chains are then separated, and a slider, box, and pin are slipped onto one chain. The finished zippers are then trucked to garment manufacturers, luggage manufacturers, fabric stores, and other companies.

English

English

عربى

عربى