Powerful Production Enterprise

Ningbo yinzhou qian run international trade Co.,Ltd. is leading

sewing thread, Embroidery Thread, Machine Embroidery Yarn supplier & manufacturer in China

, ribbons, fabrics and various clothing accessories are favored by customers due to their reliable quality, affordable prices and high-quality services.

About Us

Ningbo Yinzhou Qianrun International Trading Company, founded in 2012.

Our Factory

Have huge production development and scale, and excellent technical equipment .

Product Advantages

Manufaetrurer for morethan 25 years Specialty technology.

Market Trade

Products are widely sold to Middle East, Africa, Europe, America, South America and other regions.

M type gold and silver flat silk thread clothing underwear accessories manufacturers directly for computer embroidery thread color can be customized

M type gold and silver flat silk thread clothing underwear accessories manufacturers directly for computer embroidery thread color can be customized

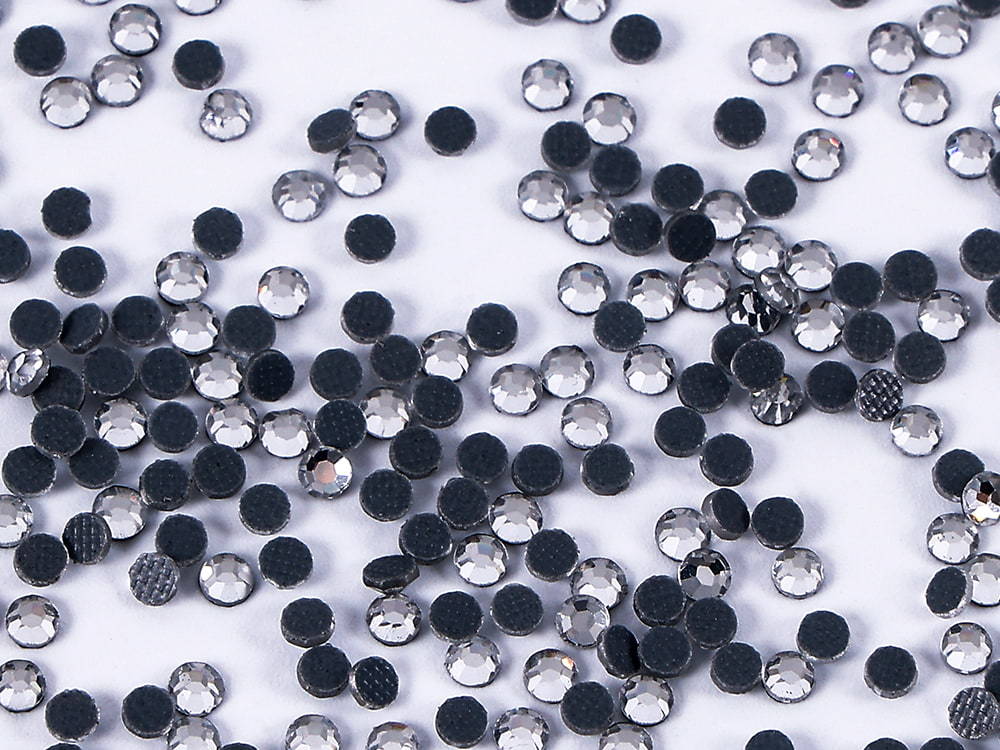

DMC ironing set hot melt glue flat iron drilling clothing DIY accessories ironing shoes bag dance skirt accessories set

DMC ironing set hot melt glue flat iron drilling clothing DIY accessories ironing shoes bag dance skirt accessories set

Stylish suit button metal hand sewn button shirt round metal secret button cross secret button gold mother button

Stylish suit button metal hand sewn button shirt round metal secret button cross secret button gold mother button